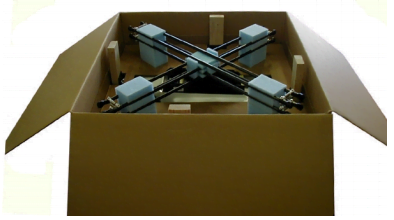

Delta robots arms made from carbon composite materials, ultra-light and ultra-stiff, ready to mount, in order to increase the speed and precision of robotic lines

Optimization is a key success factor in a majority of industries, with many plants focusing on the use of robots for tasks requiring highly repetitive and precise tasks. These include delta robots (also known as “parallel link”) whose main function is to detect, sort, and store at high speed different types of products (food, electronic components, etc.).

Delta robotic arms: the Epsilon Composite solution

Delta robot arms are generally made from high modulus carbon steel tubes with a scoop glued at each end (compatible with food applications ). Designed to be rigid and lightweight they resist accelerations of 15 G, and allow robots to perform up to 3 shots per second, with the same high precision as steel arms (much heavier and/or less stiff).

Main characteristics:

- High modulus E = 230 GPa carbon tubes

- Stainless steel scoops for food or sentitive applications,

- Anodized aluminium scoops for non-food applications,

- High precision dimensions: ± 0.1mm,

- Resists

accelerations of 15 G.