Epsilon Composite is a world leader in the design and manufacture of carbon fibre-based composite material parts.

The company is based in Gaillan en Médoc in southwestern France, where it employs 230 people.

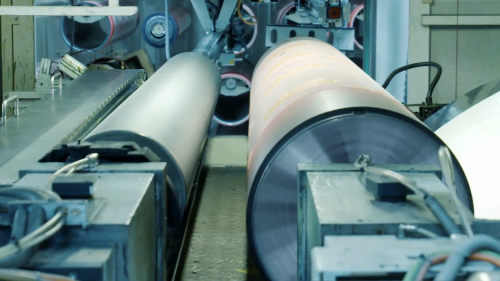

We offer tailor-made solutions for the most demanding applications thanks to an exclusive know-how based on 30 years of experience in industrial processes such as pultrusion, filament winding and various technologies for processing composite materials.

From ultra-deep water oil exploitation to aircraft structural parts, from printing machines to architectural works, we provide our customers around the world with performance improvement in the most hostile environments, thanks to innovative solutions and proven technologies.

Our activity is based on a worldwide commercial presence (90% export) and targets 4 strategic areas of activity:

- Epsilon Industries : pultruded carbon profiles and finished products for industrial and civil engineering applications.

- Epsilon Rollers : technical rollers and machine parts for conversion industries, supplied to machine manufacturers and end users.

- Epsilon Energy : pultruded cables and reinforcements for the energy industries.

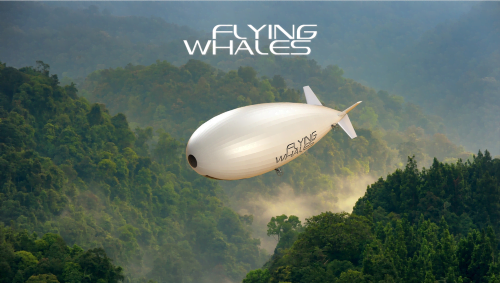

- Epsilon Aerospace : a Tier 1 supplier of carbon rods and pultruded parts for the aviation and space industries.

The dates that have marked the history of Epsilon!

Creation of Epsilon Composite by Stéphane LULL, in the composite workshop of his father, Paul LULL.

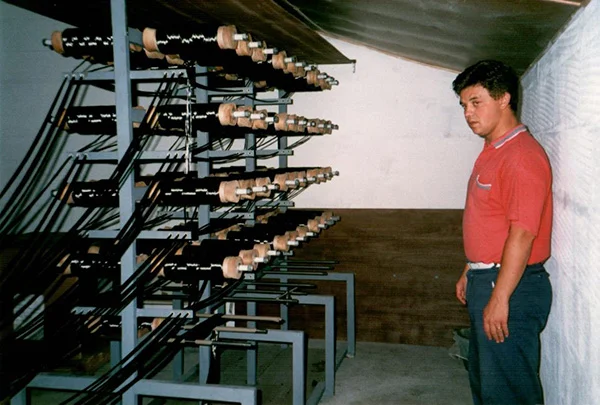

1st orders for the energy sector, for the French energy company EDF and the Italian oil group ENI. For the record, 7 of the 8 people on the picture still work for Epsilon today!

1st success in aeronautics: structural

composite profiles for military aircrafts for the Swedish manufacturer Saab

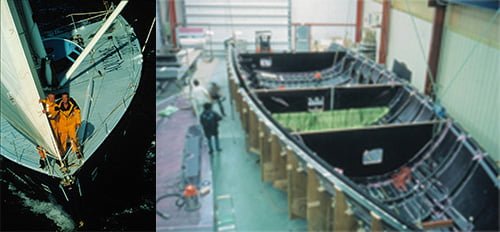

Aquitaine Innovations, the most innovative 60-foot Open sailing boat of its era, designed with the navigator Yves Parlier, with a hull and many equipments made from Epsilon Composite

pultruded carbon profiles

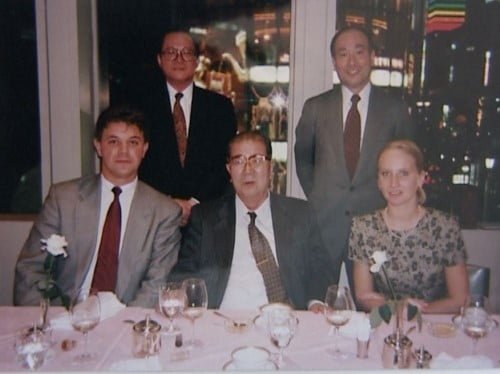

First major contracts in Japan, and the start of a long relationship with this country, where

modern carbon fibre was invented, and which was soon to become one of Epsilon Composite's main markets.

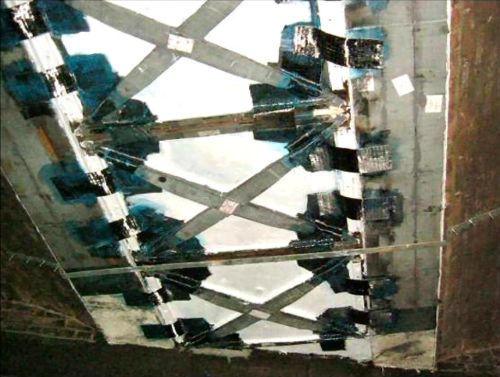

First space project for Thales, with

materials specifically developed by Epsilon to meet the requirements of the

space sector.

Development of the first composite armor for flexible risers for deep offshore

oil extraction with Technip.

Design and manufacture of structural

composite profiles for BMW, which has initiated a partnership with Epsilon Composite on the development of carbon pultrusion for future car models.

Carbon fiber sucker rods for

PetroChina, manufactured in pultrusion and incorporating metal end-fittings. One of the first finished products of Epsilon Composite, and 1st important market in China.

Carboglulam ® beams to reinforce the Hammersmith Bridge in London, after several similar successful worksites in the London Underground.

PullWinding patent, which makes it possible to manufacture very structured thin

carbon fiber tubes in pultrusion, in order to combine lightness and mechanical resistance.

Relocation of our Asian office from Singapore to Tokyo and creation of Epsilon Japan. Japan, where modern carbon fiber was invented, was at the time Epsilon's main market.

Creation of Epsilon Aerospace and intensification of our

R&D efforts in the

aerospace sector to become a Tier 1 supplier to Airbus for civil aviation programs (A330, A350XWB and A380)

Manufacturing of

giant pillars and

Carbolam ® reinforcements for the

Mataf walkway in Mecca, Saoudi Arabia, which then became the largest project in the carbon fiber industry history.

Creation of Epsilon Training, our internal training center, certified by Datadock. Every year, our apprentices and future employees are trained by our instructors and trainers on

Epsilon's main technical skills ;

pultrusion,

pullwinding, filament winding, machining, assembling, structural bonding, finishing, control, maintenance...

1st

high voltage cables reinforced with a carbon composite core installed by RTE in France. 90 kV line equipped with Nexans LoSag cables with a carbon fiber core manufactured by Epsilon Composite. See this

case study for more information.

Delivery of

Carbolam ® reinforcements for the roof of the Steve Jobs Theatre (largest monolithic carbon composite part in the world).

The elevators of Zun Tower, Beijing's highest tower (528m), are equipped with durable and eco-efficient Kone Ultrarope® carbon fiber belts. Epsilon Composite pultruded more than 500km of

carbon profiles for this record-breaking project, which follows many other projects undertaken around the world since the birth of this technology in 2008.

Completion of a major composite struts program for the Airbus A350 as a Tier 1 supplier.

1st construction site using

Carbocore ® carbon fiber anchors manufactured in pultrusion

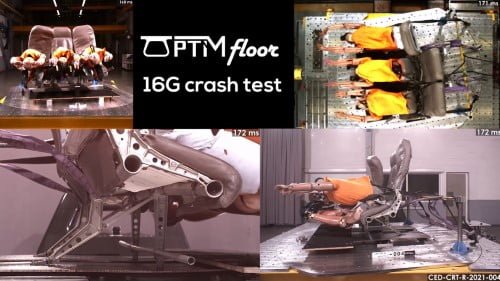

Successful 16G crash test for Optimfloor project, a 100% composite floor structure built around a complex pultruded carbon fiber stiffener.

Delivery and installation of the

composite fiber struts for the 3 last giant antennas of the Cherenkov Large-Sized Telescopes, dedicated to the observation of extragalactic objects thanks go Gamma-rays.

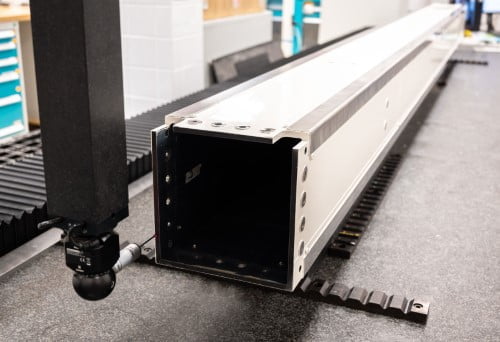

First

carbon fiber beams of the OBCL onboard loading platforms for the Airbus Beluga. Each platform is supported by 4 telescopic legs composed of several beams of 4m each.

Epsilon and its partner Somocap are awarded the GLOBAL INDUSTRIE Award 2023 for our hybrid thermoset thermoplastic overmolding process applied to carbon fiber tubes and profiles.

Read more.

Corecheck® is successfully deployed on the field for the first time. This innovative monitoring technology allows to assess the integrity of our

composite cores at various stages of the project (before, during and after installation).

The adventure continues with many projects that we often can't talk about yet!