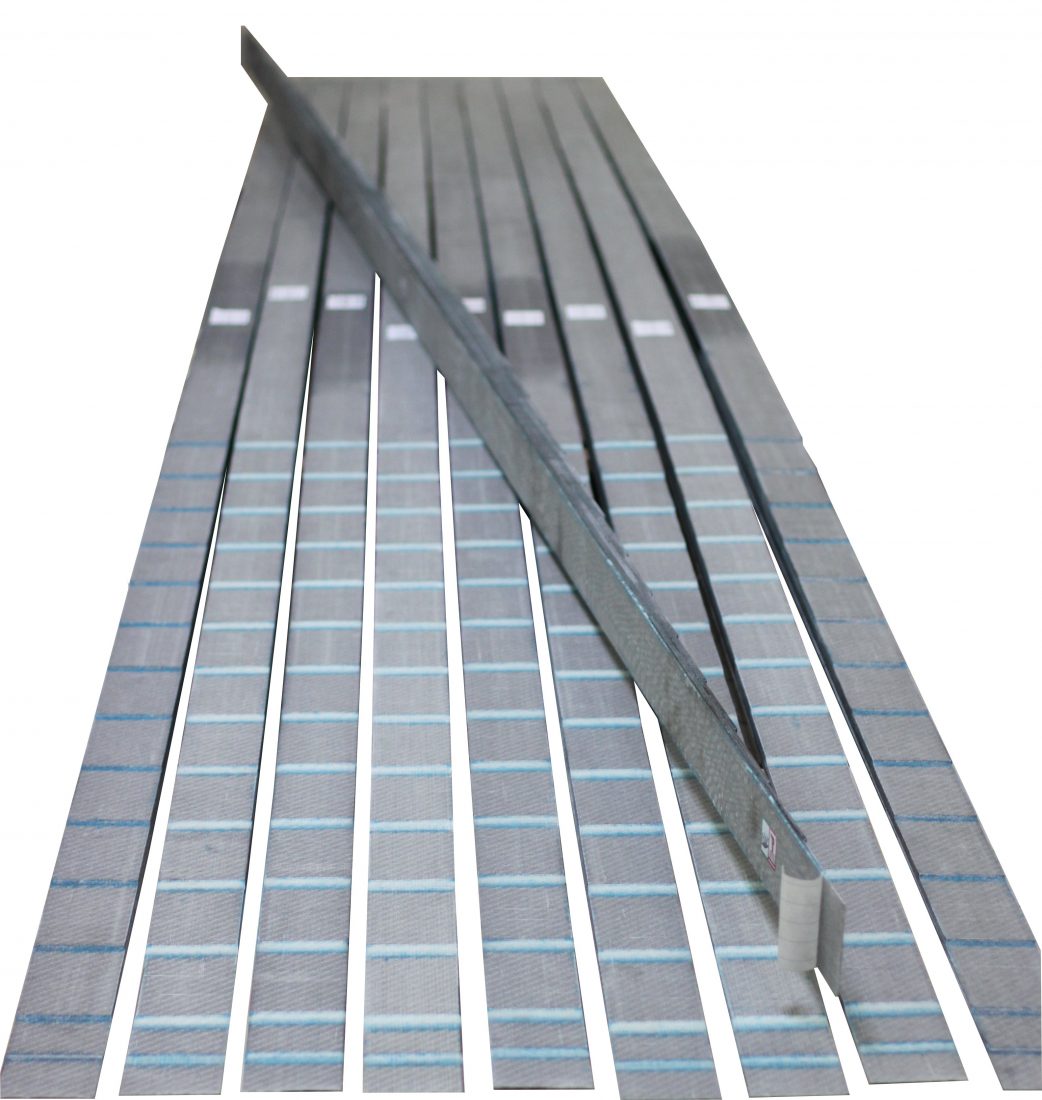

Pultruded plates in carbon fiber & epoxy resin for structural reinforcement and strengthening of civil engineering structures.

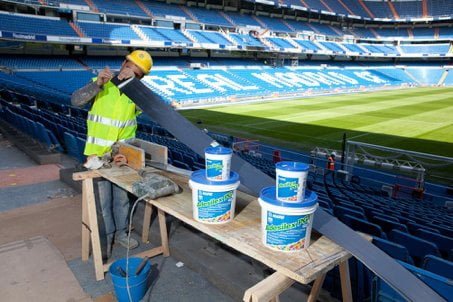

Known worldwide through the Carbolam® brand, Epsilon Composite is among the world leader in the manufacture of carbon/epoxy flat laminates for the strengthening of civil engineering structures (bridges, buildings and various structures).

| Properties | Value |

| Tensile modulus (E) | 160 to 450 GPa |

| Tensile failure stress (σ) | 1,500 to 3,000 MPa |

| Interlaminar Shear Stress (ILSS) | 70 to 100 MPa |

| Coefficient of thermal expansion (CTE) | -0.6.10^(-6) to 0.6.10^(-6) |

| Glass transition temperature (Tg) | 120 to 210°(C) |

Values provided for information only

Thanks to deep expertise in pultrusion, Epsilon Composite delivers the most efficient flat carbon reinforcements on the market

- Volume fraction of fiber (Vf) of 70%,

- Peel-ply strip on both sides for optimal bonding,

- Perfect fiber alignment.

Reinforcement of the Westgate Bridge in Melbourne: an unparalleled benchmark

In 2010, Epsilon Composite supplied Carbolam® carbon plates for what would become the largest bridge reinforcement project in the world:

- 100 km of Carbolam® provided for the addition of an extra traffic lane,

- Traffic kept flowing during the work thanks to the ease of implementation of the carbon solution.

- Read the article in Composites World on the topic.

- Read the case study on the project.

Carboglulam: evolution of Carbolam® for the manufacture of large carbon beams

Using patented technology, Carboglulam® beams consist of a successive assembly of carbon plates and are custom-made (length, width, thickness) to meet specific stiffness requirements, where Carbolam® is not sufficient anymore:

- Tensile modulus (E) from 160 to 450 GPa

- Shape: rectangular or bevelled. Can also be curved.

- Length up to 10 metres (more on request)

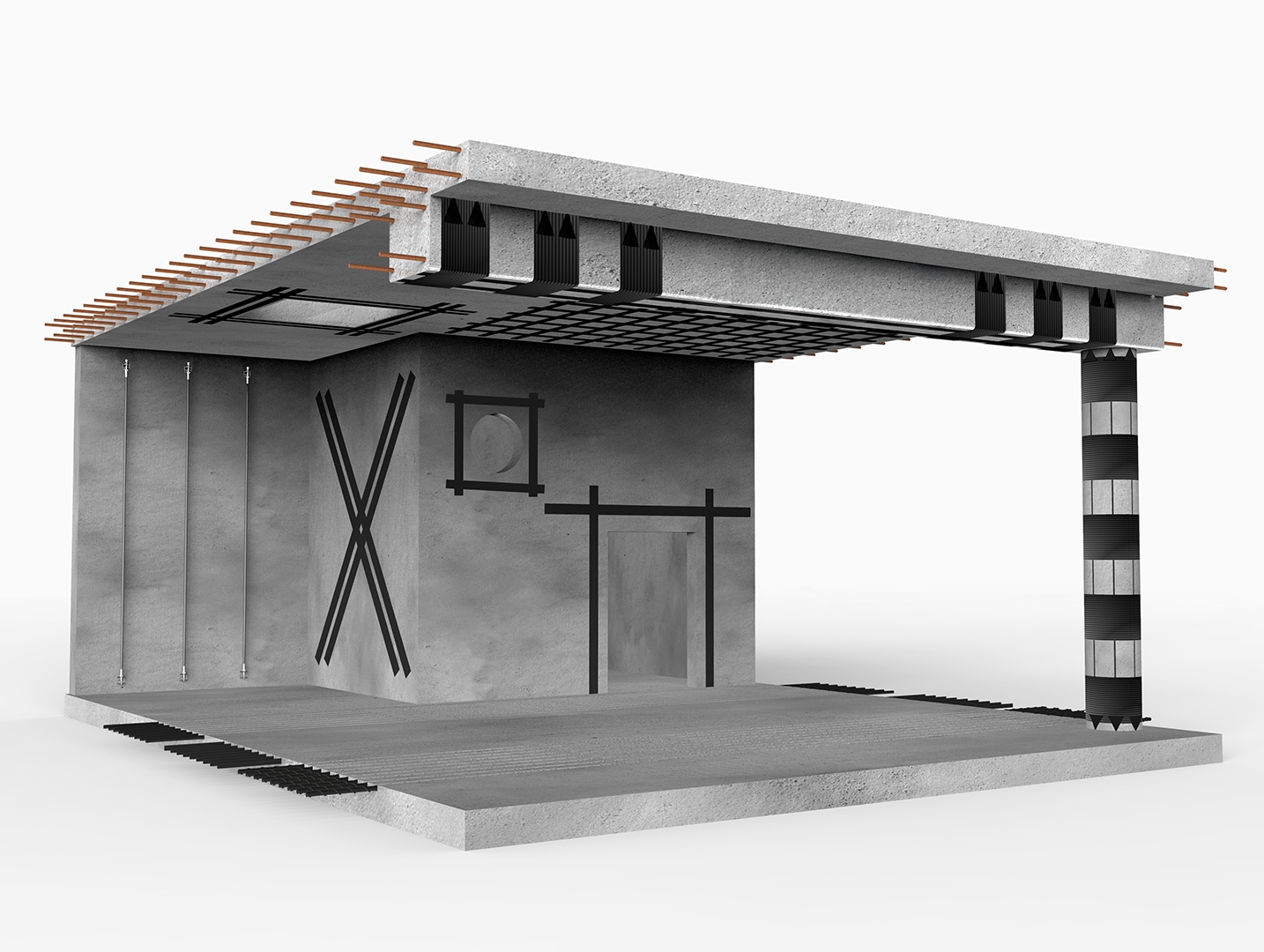

Simulation of use for our reinforcement solutions:

Reinforcement around holes

- Carbolam® plates externally bonded

- Or Near Surface Mounted reinforcements

Pre-stressed reinforcements

Pre-stressed CFRP plates or rods can be used on a wall, a slab or bridge to increase resistance and decrease deformation

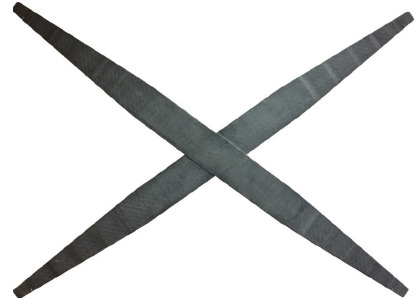

ContactSeismic reinforcement

«Cross of Saint André» pattern, from either ;

- Carbolam® plates

- Carboglulam® pre-assembled plates

Reinforcement around holes

- Carbolam® plates externally bonded

- Or Near Surface mounted reinforcements.

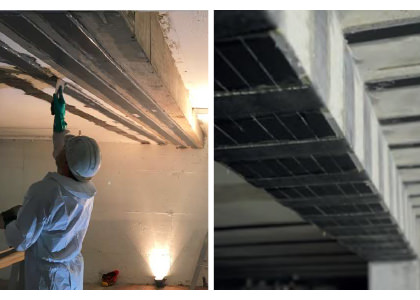

Ceiling or slab reinforcement

Carbolam® plates externally bonded to reinforce the ceiling of a RC structure (building, parking, bridge…)

ContactBeam reinforcement

3 different levels of beam reinforcement are possible:

- Level 1: Carbolam® plates can be used to reinforce a beam

- Level 2: Epsilon fabrics can be used for additional shear resistance

- Level 3 : Carbocore® CFRP anchors can be used for higher loads transmission

Pillar reinforcement

3 different levels of pillar reinforcement are possible, to replace or reinforce corroded irons, or to sustain higher loads:

- Level 1: Epsilon fabrics can be used to contain the pillar

- Level 2: Carbolam® plates can be used in addition to fabrics as flexural / buckling reinforcement, either externally bonded or Near Surface Mounted

- Level 3: Carbocore® can be used for higher loads transmission on bottom and top of pillars

Door or window lintel reinforcement

When creating an opening in a wall (door or window), 3 different levels of reinforcement are possible:

- Level 1: Carbolam® plates can be used on the lintel

- Level 2: Epsilon fabrics can be used for additional shear resistance

- Level 3: Carbocore® CFRP anchors can be used for higher loads transmission

Near Surface Mounted reinforcement

Carbolam®, Carborod®, Carbosquare® or Carbospire® invisible reinforcements for slabs, walls or pillars.

Near Surface Mounted (NSM) reinforcement are an effective way to reinforce a RC structure with minimum efforts and visual impact, or in case of limited space.

It also minimize the risk of debonding between CFRP & concrete